About Us

- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

Views: 0 Author: VIGORAWINDOWS Publish Time: 2026-02-13 Origin: Site

Table of Contents

When overseas distributors are sourcing windows and doors for projects, “price difference” is often the first question they ask. Especially in markets such as the Middle East, Africa, Southeast Asia, and South America—where buyers are cost-sensitive but still value durability—customers usually make direct comparisons:

How much is the price difference between uPVC windows and aluminium windows in bulk orders?

In fact, there is no single answer to this question. Pricing depends not only on the material itself, but also on structural design, glass configuration, hardware systems, order quantity, transportation methods, and many other factors. Below, we will combine VIGORAWINDOWS’ real export business experience to systematically analyze the price gap and the logic behind it in bulk orders.

From the perspective of raw materials, uPVC usually has a more obvious price advantage.

1. Raw material sources and cost structure

uPVC (Unplasticized Polyvinyl Chloride) belongs to plastic steel profiles.

Aluminium is a metal profile that requires smelting and extrusion processes.

Aluminium prices are more affected by fluctuations in the global metal market.

According to public data from the International Aluminium Institute:

“Aluminium production is energy-intensive, making its price sensitive to electricity and raw material costs.”

This means that when energy prices rise, aluminium profile costs increase significantly, while uPVC is less affected.

2. Bulk procurement unit price range (industry reference)

Taking standard configurations (double glazing, regular hardware) as an example:

| Product Type | Bulk Unit Price Range (FOB) |

| uPVC windows | $45–80 / m² |

| aluminium glass window | $70–120 / m² |

In bulk orders, uPVC is usually 20%–35% lower than aluminium.

Although aluminium is more expensive, distributors are still willing to purchase it because of performance differences.

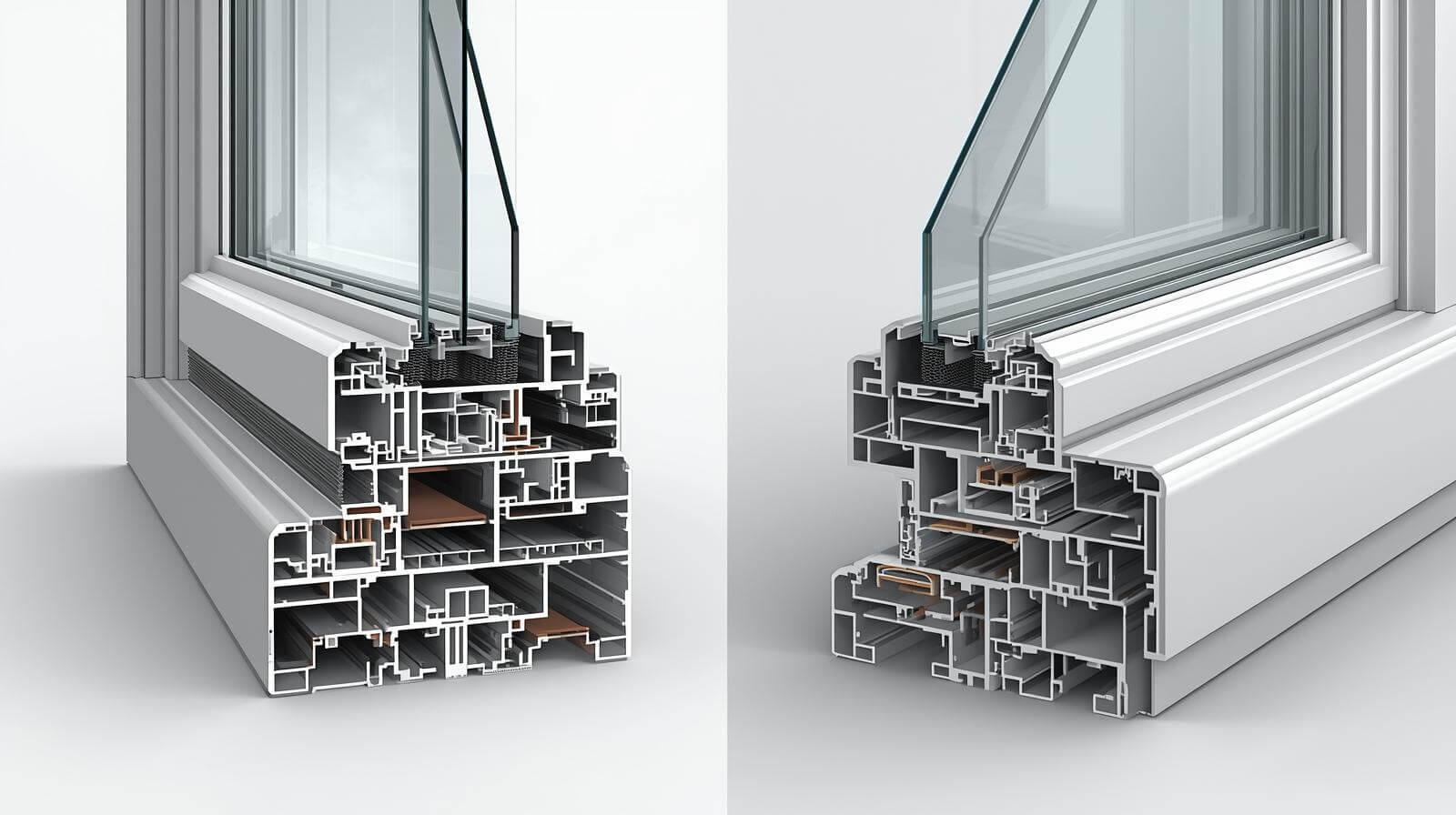

1. Strength and size capability

Aluminium has higher strength.

It can be used for extra-large windows and floor-to-ceiling designs.

It is suitable for commercial projects and high-rise buildings.

uPVC is more suitable for residential and medium-size window openings.

According to a UN-Habitat building materials report:

“Lightweight metals such as aluminium are widely used in urban high-rise facades due to their strength-to-weight ratio.”

2. Service life

Aluminium: More than 20–30 years

uPVC: 15–25 years

In high-temperature and high-UV regions (such as the Middle East and Africa), aluminium shows more stable weather resistance.

In real export orders, material is not the only determining factor.

1. Glass configuration

| Configuration | Price Impact |

| Single glazing | Base price |

| Double glazing | +15%–25% |

| Low-E | +25%–40% |

According to research from the International Energy Agency (IEA):

“Double glazing can reduce heat loss by up to 50% compared to single glazing.”

This is also why customers in the Middle East and Southeast Asia widely adopt double glazing.

2. Hardware systems

German hardware is more expensive than domestic hardware.

Heavy-duty roller systems cost more.

Folding door hardware has the highest cost.

3. Surface treatment (aluminium only)

| Process | Price Impact |

| Powder coating | Base |

| PVDF coating | +20% |

| Wood grain transfer | +25% |

4. Order quantity

Based on VIGORAWINDOWS’ actual export orders:

Under 50 sets: Higher unit price

100–300 sets: Price decreases by 8%–15%

Full container orders: Best pricing

Different regions have different acceptance levels regarding price differences.

Middle East Market

Prefers aluminium

Focuses on heat resistance and sand resistance

Accepts higher unit prices

African Market

More price-focused

Higher proportion of uPVC

Southeast Asia

Balanced demand for both

Humid climate promotes uPVC growth

According to the World Bank building energy efficiency program report:

“Affordable insulation materials are key to improving building efficiency in developing regions.”

Because of its insulation performance and lower cost, uPVC demand continues to grow in developing countries.

South American Market

Residential projects dominate

Custom-color aluminium demand is increasing

In bulk procurement decisions, distributors evaluate not only unit prices but also supplier capabilities.

1. Product diversification

As a professional upvc door and window company and aluminium window manufacturer, we provide:

aluminum windows

aluminium doors

UPVC windows

UPVC doors

This enables one-stop procurement for distributors.

2. Customization capability

We support:

custom upvc window size customization

Color customization

Glass configuration customization

Hardware brand customization

This is especially important for project supply.

3. Source of price advantage

Our price advantage does not come from low pricing alone, but from:

China’s mature supply chain

Bulk raw material procurement

Standardized production processes

Therefore, we maintain competitiveness while ensuring product quality.

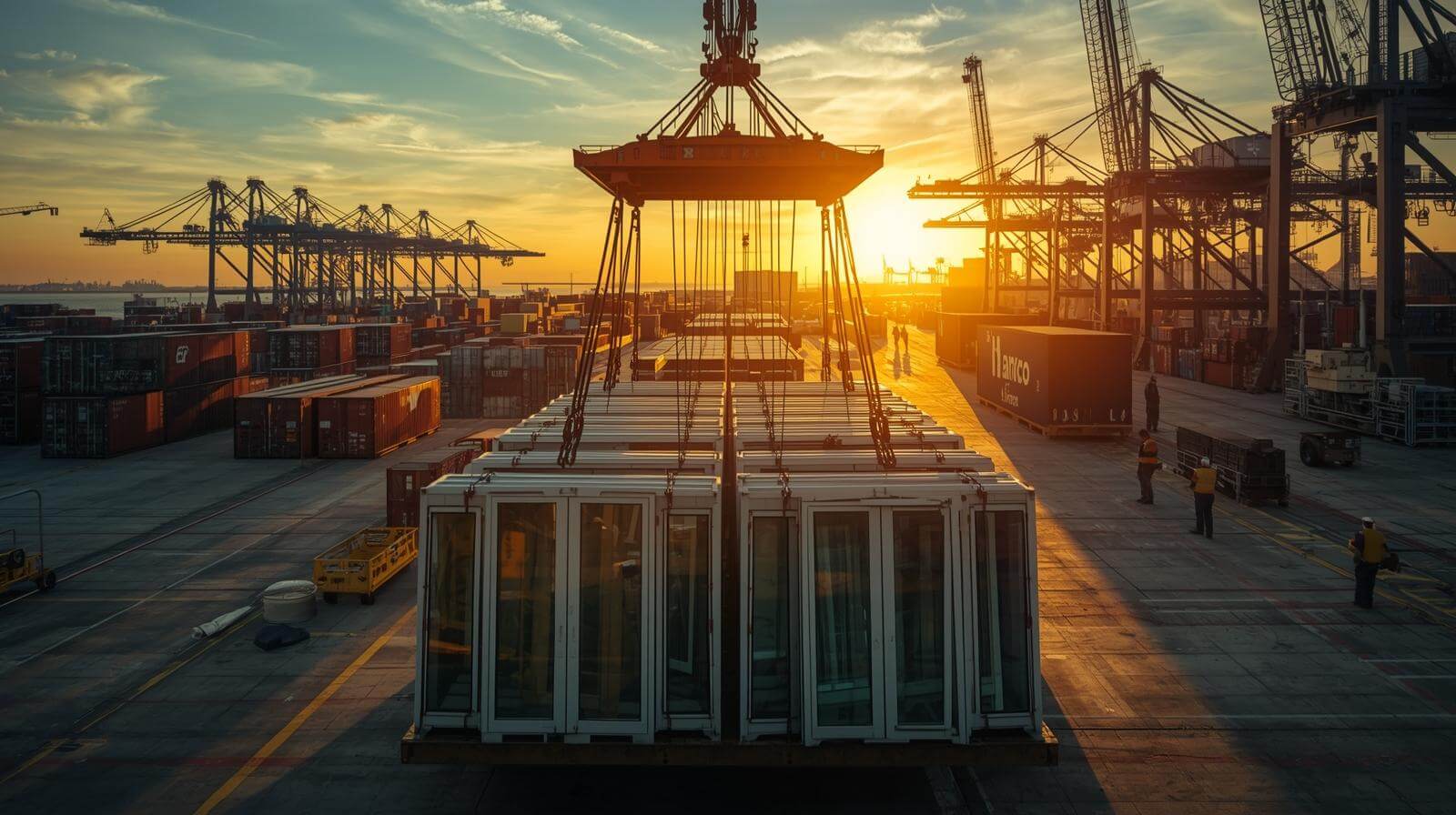

4. Fast delivery

Regular orders: 15–25 days

Project orders: 30–40 days

Full container and LCL both supported

This is critical for projects with tight schedules.

If distributors want to quickly evaluate the price difference, they can follow this logic:

1. Project type

Residential → uPVC is more economical

Commercial → aluminium is more suitable

2. Window size

Large size → aluminium

Standard size → uPVC

3. Budget positioning

Low-cost projects → uPVC

High-end projects → aluminium

A Practical Example from Our Export Experience

In a 200-unit residential window project we supplied to an African distributor:

Total uPVC solution price: About $38,000

Total aluminium solution price: About $52,000

The difference was about 27%, but:

Aluminium was more suitable for high-end housing sales.The client finally chose mixed procurement (70% uPVC + 30% aluminium).This combination is also a mainstream strategy among many distributors today.

When discussing the bulk price difference between uPVC and aluminium windows, the essence is not simply “which is cheaper,” but rather:

Different project positioning

Different market demands

Different performance requirements

uPVC stands out for cost performance and energy efficiency, making it suitable for large-volume residential projects.Aluminium, with its strength, size capability, and appearance advantages, is more suitable for commercial and high-end developments.

For overseas distributors, the ideal approach is often not choosing one over the other, but combining product lines based on market needs.

VIGORAWINDOWS follows this strategy by providing flexible bulk customization solutions—ensuring quality, delivery time, and competitive pricing while helping distributors achieve higher profit margins and project success rates in regional markets.